Types of Nuts

types of nuts

Nuts come in various sizes, shapes, materials, and thread patterns. With such a diverse range, it’s essential to pick the correct fastener for your specific application. For example, Aluminium fasteners are valued for their excellent electrical and thermal conductivity while Titanium is favored for lightness, corrosion resistance, and strength.

The hexagonal nut is the most commonly used nut across industries. That being said, there are other types of nuts, each suitable for specific applications and circumstances.

In this section, I’ll tackle the different types of nuts, their standout characteristics, and their common applications.

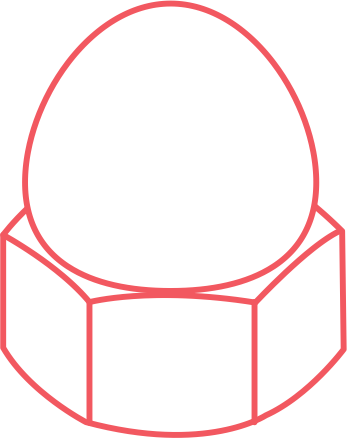

Acorn Nuts

Acorn nuts are a type of cap nut. They get their name from the acorn-shaped cap at the top.

Just like with any other cap nut, this head serves both a cosmetic and functional purpose. The acorn-shaped cap safeguards the bolt’s end and creates an overall clean look. It also minimizes the risk of clothes snagging (getting caught) on the sharp edges. Acorn nuts are widely used across all industries.

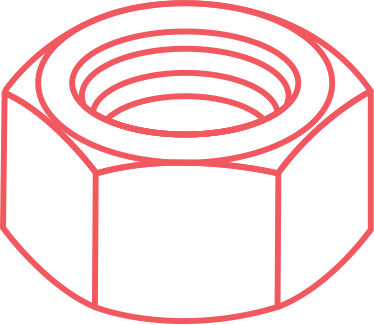

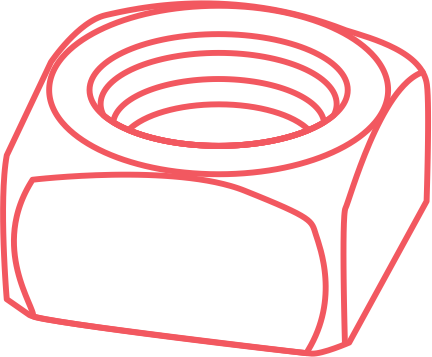

Hex Nuts

A hex nut is the most commonly used nut type across industries. It gets its name from its shape – it’s six-sided or hexagonal-shaped. The hex nut is preferred since its shape makes it relatively easy to fasten and unfasten.

There are different types of hex nuts, each with properties that set it apart. They include;

Hex Finish Nuts: A hex finish nut is a standard hex-shaped fastening device. It features a circular cross-section and internal threads.

Structural Heavy Hex Nuts: As the name implies these nuts are heavier, thicker, and stronger than a standard hex nut. This property makes them ideal for applications that need an especially strong connection.

Small Pattern Hex Nuts: These hex nuts simply have smaller dimensions. They are typically 20% narrower than standard nuts. The smaller size means that small pattern hex nuts are a great option for tight spaces where regular fasteners can’t fit.

Jam Nuts

A jam nut is hex-shaped and it’s usually half the size of a regular nut. It is usually “jammed” against a standard nut to secure it in place and prevent loosening. A jam nut is necessary if the regular nut keeps loosening or falling off.

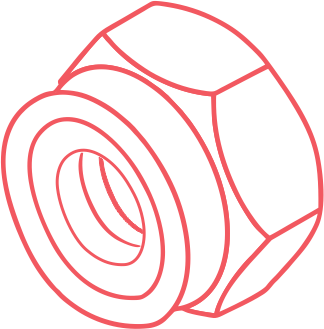

Lock Nuts

A lock nut is specially designed to withstand vibrations and torque without loosening. Therefore, this type of fastener will have a locking mechanism to ensure secure connections.

There are different types of lock nuts in the market. While they all utilize different locking mechanisms, they share a common goal of preventing loosening. Common types of lock nuts include;

Prevailing Torque Lock Nuts: Also known as stover nuts, prevailing torque nuts are equipped with a conical top. Distortion in the cone top provides its locking properties.

Serrated Flange Lock Nut: As the name suggests, this nut comes fitted with a serrated flange. Upon tightening, the serrations create a locking action that prevents the nut from loosening or falling off.

Castle Lock Nut: Also known as a castellated or slotted nut, this fastening device is designed with slots on one end. These slots provide an extra layer of security against loosening or unscrewing. Castellated nuts are popular in the automotive industry for applications such as securing wheels and bearings.

Nylon Insert Lock Nut: The locking mechanism of this nut comprises a layer of nylon positioned within the threaded center. The nylon provides a stronger grip and prevents vibration-related loosening. The nylon insert lock nut is widely used when assembling computers and cars.

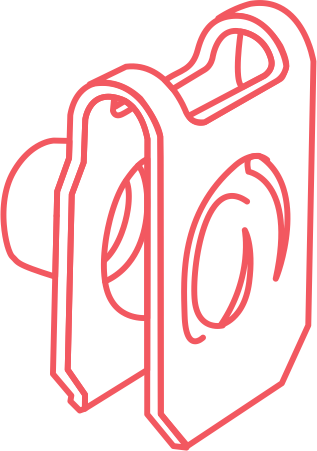

Push Nuts

A push nut is simply “pushed on” to a bolt or shaft to secure it. This easy, sliding application process contributes to the popularity of the push nut.

Conversely, push nuts are hard to remove since they’re built to prevent loosening. They have a variety of applications ranging from medical equipment to kids’ toys.

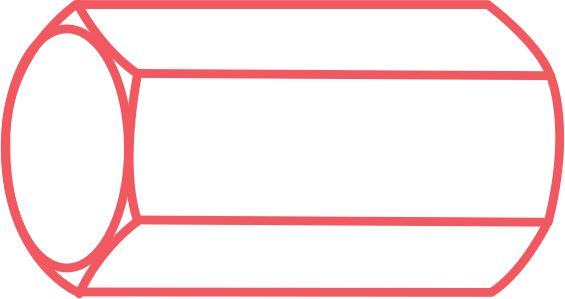

Coupling Nuts

The coupling nut is not your typical bolt nut. It’s used to connect two fittings that both have external male threads. As coupling nuts are not meant for bolts, they’re typically longer than regular bolts.

Also known as extension nuts or rod coupling nuts, these fasteners are a go-to when linking threaded rods or pipes.

Speed Nuts

Speed nuts, aka sheet metal nuts or Tinnerman nuts, are clip-like fasteners that get their name from their quick and easy installation process. All you have to do is screw the nut onto the bolt without a wrench or any other specialized equipment. Speed nuts are commonplace in the automotive industry.

Square Nuts

As the name implies, a square nut is 4-sided. Its square-like shape allows for greater surface contact area which translates to a stronger connection. A square nut is, therefore, less likely to loosen and slip off. This fastening hardware is mostly used with a square head bolt.

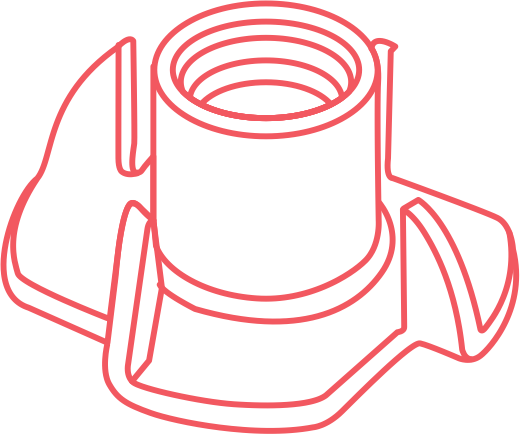

T-Nuts

T-Nuts, also known as tee-nuts, resemble the letter T and have a pronged flange on one end. These hooks or prongs embed into the material being fastened to improve the joining capabilities of the nut. T-nuts are often used to secure materials such as wood or plastic.

U-Nuts

U-Nuts, alias spire nuts or chimney nuts, get their name from their U-shaped profile. These fasteners are time-saving and cost-efficient since they do not require any special tools to tighten. Spire nuts are used when connecting sheets of materials.

Wing Nuts

These internally-threaded nuts are equipped with wings on either side. The side wings allow for an effortless setup. Wing nuts are the perfect solution in situations where nuts need to be fastened or removed frequently.

_1.jpg)